High Efficiency!

Low Cost and Long Life

Simple Operation and Maintenance

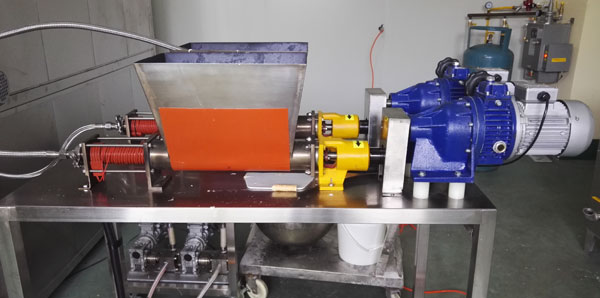

Mingjie Pump is a professional large-flow, high pressure, high viscosity and accurately measured progressive cavity pump manufacturer and supplier.

Friendly Reminder

Please provide the physical and chemical properties of the medium you are transporting before selecting the model. At the same time, specific flow, head or pressure also need to be provided. So that we can choose the model and quotation for you faster.

| Pump Type | Pressure Range (bar) | Capacity Range (m³/h) | Speed Range (rpm) | Inlet Size (G/DN) | Outlet Size (G/DN) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| MJN025-2S | 0~12 | 0~0.25 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-1L | 0~6 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-2S | 0~12 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-1L | 0~6 | 0~1 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-2S | 0~12 | 0~1 | 0~350 | 50 | 50 | 1.5 |

| MJN1-4S | 0~24 | 0~0.5 | 0~250 | 50 | 50 | 3 |

| MJN3-1L | 0~6 | 0~3 | 0~350 | 50 | 50 | 2.2 |

| MJN3-2S | 0~12 | 0~2.5 | 0~350 | 65 | 65 | 3 |

| MJN3-4S | 0~24 | 0~1.5 | 0~250 | 65 | 65 | 5.5 |

| MJN5-1L | 0~6 | 0~5 | 0~320 | 65 | 65 | 3 |

| MJN5-2S | 0~12 | 0~5 | 0~320 | 80 | 80 | 4 |

| MJN5-3S | 0~18 | 0~3 | 0~250 | 80 | 80 | 5.5 |

| MJN5-4S | 0~24 | 0~2 | 0~200 | 80 | 80 | 7.5 |

| MJN10-1L | 0~6 | 0~10 | 0~300 | 80 | 80 | 4 |

| MJN10-2S | 0~12 | 0~7 | 0~300 | 80 | 80 | 5.5 |

| MJN10-3S | 0~18 | 0~6 | 0~250 | 80 | 80 | 7.5 |

| MJN10-4S | 0~24 | 0~4 | 0~200 | 80 | 80 | 11 |

| MJN15-1L | 0~6 | 0~15 | 0~300 | 80 | 80 | 5.5 |

| MJN15-2S | 0~12 | 0~12 | 0~300 | 100 | 100 | 7.5 |

| MJN15-3S | 0~18 | 0~10 | 0~250 | 100 | 100 | 11 |

| MJN15-4S | 0~24 | 0~7 | 0~200 | 100 | 100 | 15 |

| MJN25-1L | 0~6 | 0~25 | 0~280 | 100 | 100 | 7.5 |

| MJN25-2S | 0~12 | 0~22 | 0~300 | 125 | 125 | 11 |

| MJN25-3S | 0~18 | 0~15 | 0~250 | 125 | 125 | 15 |

| MJN25-4S | 0~24 | 0~12 | 0~200 | 125 | 125 | 18.5 |

| MJN50-1L | 0~6 | 0~50 | 0~280 | 125 | 125 | 11 |

| MJN50-2S | 0~12 | 0~35 | 0~250 | 150 | 150 | 22 |

| MJN50-3S | 0~18 | 0~30 | 0~230 | 150 | 150 | 30 |

| MJN50-4S | 0~24 | 0~26 | 0~200 | 150 | 150 | 37 |

| MJN80-1L | 0~6 | 0~80 | 0~280 | 150 | 150 | 22 |

| MJN80-2S | 0~12 | 0~60 | 0~280 | 150 | 150 | 37 |

| MJN80-3S | 0~18 | 0~42 | 0~200 | 150 | 150 | 45 |

| MJN80-4S | 0~24 | 0~25 | 0~150 | 150 | 150 | 55 |

| MJN120-1L | 0~6 | 0~120 | 0~250 | 150 | 150 | 37 |

| MJN120-2S | 0~12 | 0~100 | 0~270 | 200 | 200 | 45 |

| MJN120-3S | 0~18 | 0~60 | 0~180 | 200 | 200 | 55 |

| MJN120-4S | 0~24 | 0~50 | 0~150 | 200 | 200 | 55 |

| MJN180-1L | 0~6 | 0~180 | 0~220 | 200 | 200 | 45 |

| MJN180-2S | 0~12 | 0~170 | 0~220 | 200 | 200 | 55 |

| MJN300-1L | 0~6 | 0~300 | 0~220 | 200 | 200 | 55 |

Some famous progressive cavity pump manufacturers

- Seepex, Inc. — Brand: Seepex pump (Country: American)

- Erich NETZSCH GmbH & Co. Holding KG — Brand: Netzsch pump (Country: Germany)

- Moyno In — Brand: Moyno pump (Country: Germany)

- NOV Process & Flow Technologies UK Limited — Brand: Mono pump (Country: UK)

- MXQ, LLC. — Brand: MXQ pump (Country: USA)

- ITT Bornemann GmbH — Brand: Bornemann pump (Country: Germany)

- PCM Group UK Ltd — Brand: PCM pump (Country: French)

- Allweiler Group GmbH — Brand: Allweiler pump (Country: Germany)

- 兵神装備株式会社 / HEISHIN Ltd. — Heishin pump (Country: Japan)

- ROTO PUMPS LTD. — Roto pumps (Country: India)

We can provide after-sales replacement spare parts and complete pump repair services for these pump manufacturers.

Transport Characteristics:

Flow rate and pressure are depending on pump size, geometry and stages of the conveying elements and have to be defined depending on medium and application.

Advantages:

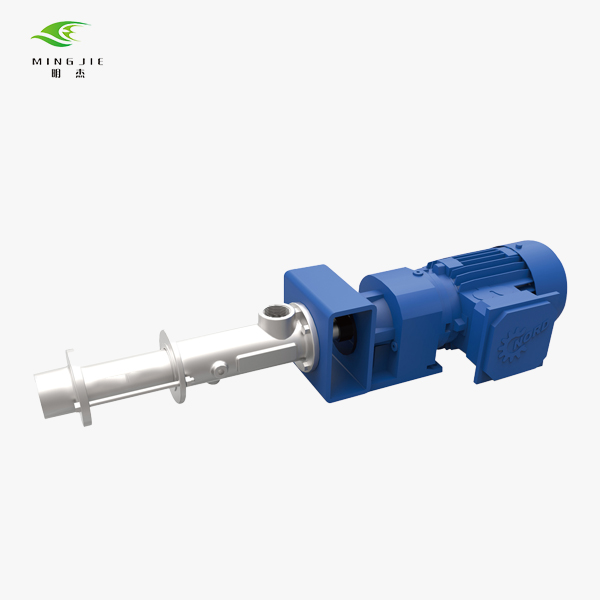

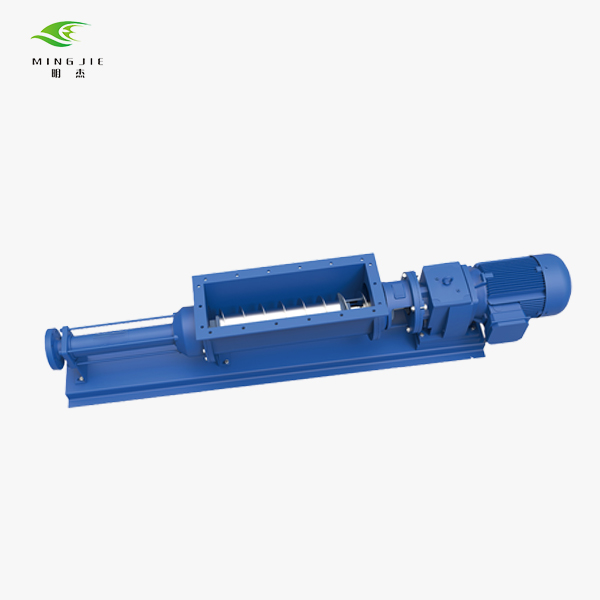

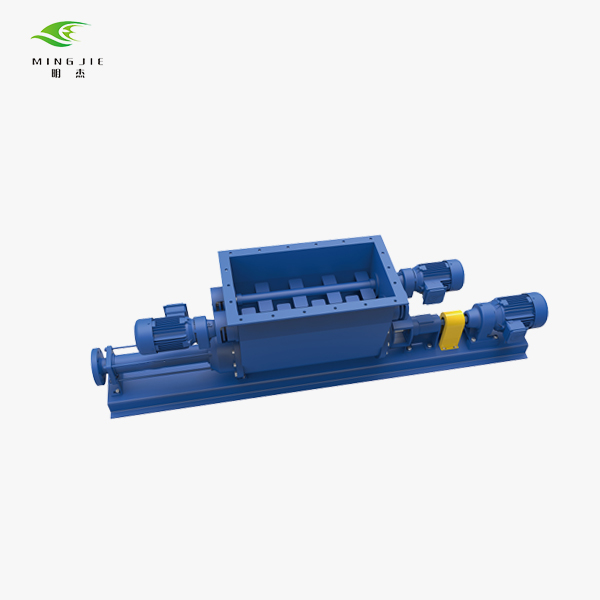

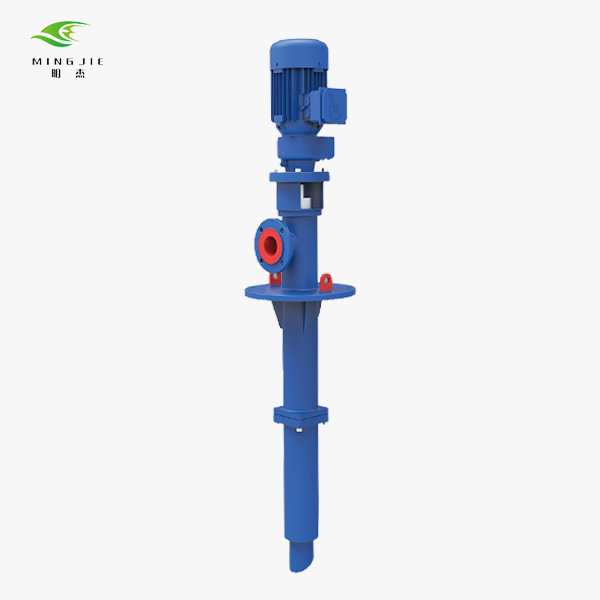

What is a

Progressive Cavity Pump ?

Progressive cavity pump is a type of positive displacement pump, which is a rotary positive displacement pump;

It was invented by the French engineer MoiNeau, and first produced by the French PCM Pump Company, so it is also called Mono pump, PC pump or PCM pump;

It has been officially named as single screw pump (单螺杆泵) or eccentric screw pump (偏心螺杆泵) in China;

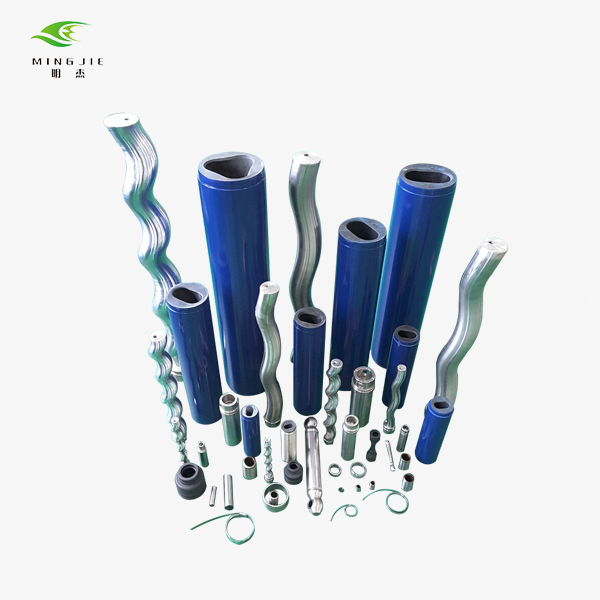

It is mainly composed of a single-head spiral rotor (solid metal of different materials) and a double-head inner spiral stator (flexible rubber) (of course, our factory also has a double-head spiral rotor and a three-head inner spiral stator). Due to the irregular shape of the stator and the rotor, they mesh with each other to form a number of different sealed cavities, which separate the suction cavity and the discharge cavity, resulting in volume changes to achieve the purpose of liquid delivery; The stator and the rotor are interference fit, should not be run dry. The conveyed medium can act as a lubricant.

Because of its high process reliability and suction capability, it is usually used for continuous, gentle conveying and precise feeding;

Progressive Cavity Pumps Working Principle

The progressive cavity pump is a kind of internal meshing closed rotor positive displacement pump. Its main working parts are composed of an eccentric screw (rotor) and a fixed elastic bushing (stator).

The rotor is a screw with a large lead, a large tooth height and a small thread inner diameter, while the stator is an elastic bushing with a double-ended spiral.

Due to the special geometric shapes of the stator and the rotor, they will form several separate sealed cavities that are not connected to each other.

When the rotor is running in the stator, the sealed cavity moves in the axial direction from the suction end to the discharge end of the pump.

The medium is continuously and uniformly conveyed in the coaxial line from the suction side to the pressure side without changing the volume.

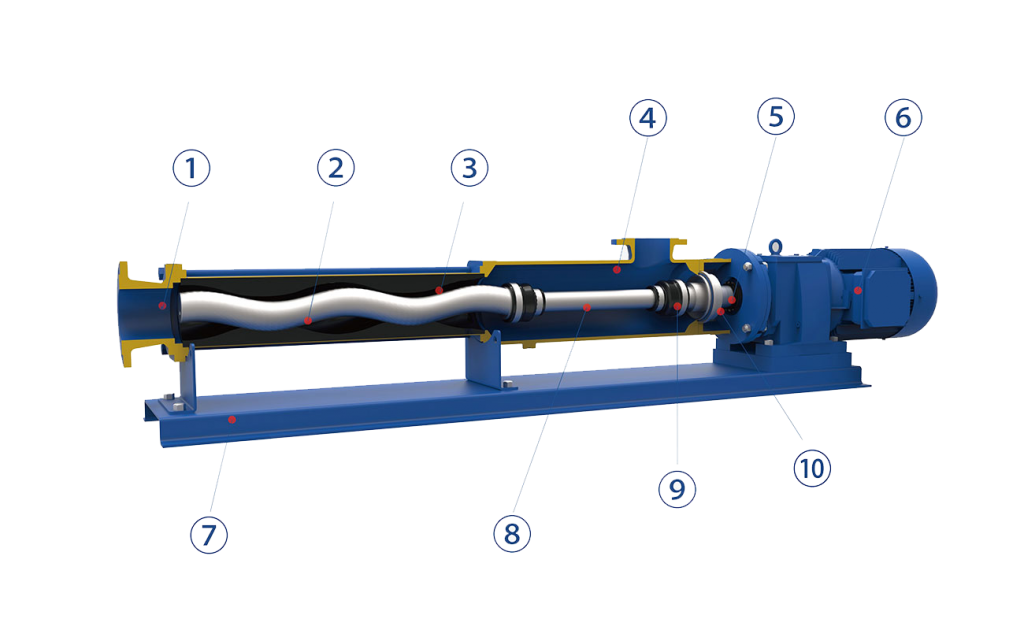

Structure Diagram

| No. | Name | Matiral |

|---|---|---|

| 1 | Material-out chamber | HT200, 1Cr18Ni9Ti, 304, 316L, 2205, Ti |

| 2 | Rotor | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 3 | Stator | NR, NBR, Q, EPM, FKM |

| 4 | Suction chamber | HT200, 304, 316L, 2205, Ti |

| 5 | Driving shaft | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 6 | Gear motor | / |

| 7 | Base plate | 45#, 2Cr13, 304, 316L, 2205, Ti |

| 8 | Coupling rod | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 9 | Universal joint assembly | NBR + 45#, 2Cr13, 304, 316L |

| 10 | Shaft sealing | Customized according to media |