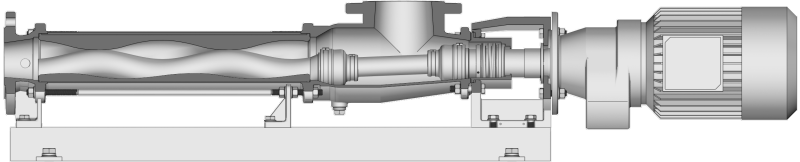

High quality replacement spare parts for Seepex PC Pump.

✔︎ 25 years of SEEPEX spare parts supply experience

✔︎ Have the full model of Seepex® BN, BT, MD… series

✔︎ 100% Compatible stator and rotor for all applications

✔︎ Connecting rod, universal joint assembly, drive shaft, mechanical seal or packing seal, …

✔︎ Have a variety of materials

Home>Progressive cavity pump spare parts>Seepex PC parts

Mingjie Pump manufactures, distributes and sells aftermarket spare parts for SEEPEX® pumps. We have already had a large number of successful application cases of replacing spare parts of Seepex. Moreover, we have the ability to deliver quickly, without affecting the quality, and can suggest you new rubber compounds and basic materials, which have delayed the service life of your pump.

Seepex is a manufacturer of progressive cavity pumps and macerators based in Germany since 1972. The main fields of application are marine, oil and gas, paper and pulp, agriculture, food and many more.

Mingjie Pump has extensive experience in manufacturing seepex pump spare parts and replacement pumps.

Seepex complete range of spare parts

Mingjie Pump offers all kinds of 100% compatible Seepex spare parts with the highest quality standards at the best price.

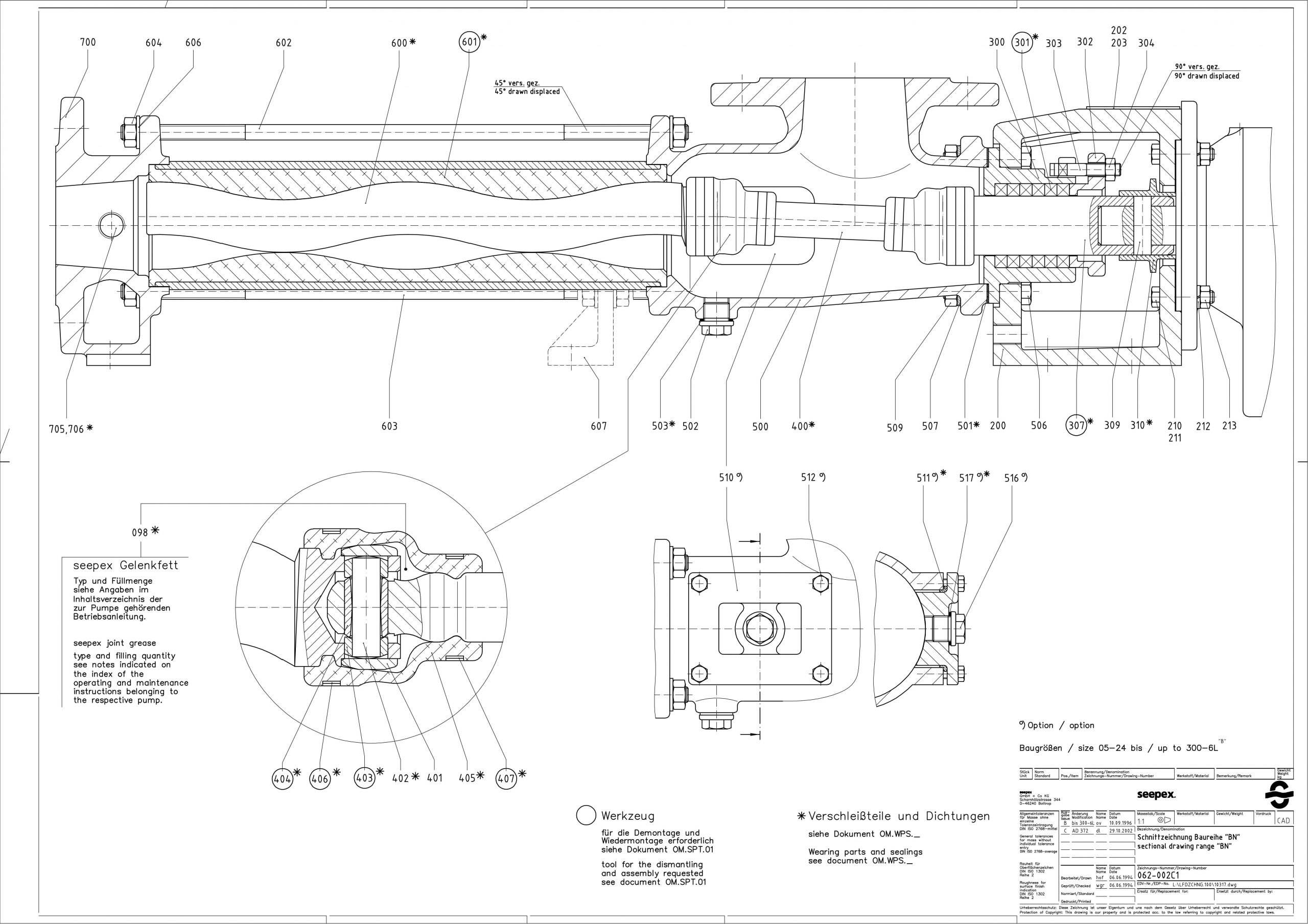

Seepex BN series spare parts list

Applicable models 05-24, 1-6, 1-12, 2-6L…. .202-6L

| German | English | French | ||

| Stückliste Baureihe BN Baugrössen Schnittzeichnung Nr. | Parts list range BN sizes sectional drawing No. | Liste des pièces série BN tailles plan no. | ||

| Quantity | Pos. No. | Benennung Stck. / Pos. | denomination Qty. / item | désignation Qté. / Poste |

| 1 | 200 | Laterne | lantern | lanterne |

| 2 | 202 | Halbrundkerbnägel | round head grooved pins | rivet |

| 1 | 203 | Typenschild | type plate | palque signalitique |

| 4 | 210 | 6kt-Schraube | hexagon bolt | vis |

| 211 | 6kt-Schraube | hexagon bolt | vis | |

| 4 | 212 | Federring | spring washer | rondelle frein |

| 4 | 213 | 6kt-Mutter | hexagon nut | écrou |

| 1 | 307 | Steckwelle | plug-in shaft | arbre à broche |

| 1 | 309 | Steckwellenbolzen | plug-in shaft pin | cheville pour arbre à broche |

| 1 | 310 | Spritzring | splash ring | bague de projection |

| 1 | 400 | Kuppelstange | coupling rod | barre d’ accouplement |

| 2 | 401 | Gelenkhülse | retaining sleeve | douille d’ articulation |

| 2 | 402 | Kuppelstangenbolzen | coupling rod pin | axe d’ articulation |

| 4 | 403 | Führungsbuchse | guide bushing | douille de guidage |

| 2 | 404 | Kuppelstangenbuchse | coupling rod bushing | chemise d’ axe |

| 2 | 405 | Manschette | universal joint sleeve | manchette |

| 2 | 406 | Halteband | holding band | collier de serrage |

| 2 | 407 | Halteband | holding band | collier de serrage |

| 1 | 500 | Sauggehäuse | suction casing | carter d’ aspiration |

| 1 | 501 | Sauggehäusedichtung | casing gasket | étanchéité du carter d’ aspiration |

| 3 | 502 | Verschlussschraube | screwed plug | bouchon de vidange |

| 3 | 503 | Dichtring | sealing ring | joint d’ étanchéité |

| 4 | 506 | 6kt-Schraube | hexagon bolt | vis |

| 4 | 507 | Fächerscheibe | fan type lock washer | rondelle à dents chevauchantes extérieures |

| 4 | 509 | 6kt-Mutter | hexagon nut | écrou |

| 2 | 510 | Reinigungsdeckel | cleanout | couvercle de nettoyage |

| 2 | 511 | Dichtung | gasket | étanchéité |

| 8 | 512 | 6kt-Schraube | hexagon bolt | vis |

| 2 | 516 | Verschlussschraube | screwed plug | bouchon de vidange |

| 2 | 517 | Dichtring | sealing ring | joint d’ étanchéité |

| 1 | 600 | Rotor | rotor | rotor |

| 1 | 601 | Stator | stator | stator |

| 2 | 602 | Spannschraube | tie bolt | tirant |

| 2 | 603 | Spannschraube | tie bolt | tirant |

| 8 | 604 | 6kt-Mutter | hexagon nut | écrou |

| 8 | 606 | Scheibe | washer | rondelle |

| 1 | 607 | Stützbock | trestle | pied |

| 1 | 700 | Druckstutzen | pressure branch | bride de refoulement |

| 1 | 705 | Verschlussschraube | screwed plug | bouchon de vidange |

| 1 | 706 | Dichtring | sealing ring | joint d’ étanchéité |

| 098 | seepex Gelenkfett | seepex joint grease | seepex graisse d’ articulations |

- This parts list is applicable to BN series whose seal is mechanical; Applicable models: Applicable models 05-24, 1-6, 1-12, 2-6L…. .202-6L

- For a list of seepex packing seal BN series spare parts, please see the manual provided herein. Applicable models: 05-24 … 300-6L

Seepex model table

| Model | Model | Model |

|---|---|---|

| MD0005-24 | BN5-48 | BN55-6LT |

| MD0015-24 | BN10-6L | BN55-12T |

| MD003-12 | BN10-12 | BN70-6L |

| MD003-24 | BN10-24 | BN70-12 |

| MD006-12 | BN10-48 | BN70-18 |

| MD006-24 | BN14-12 | BN70-24 |

| MD01-48 | BN15-6LT | BN70-48 |

| MD012-12 | BN15-12T | BN75-6LT |

| MD012-24 | BN17-6L | BN100-6L |

| BN025-6L | BN17-12 | BN100-18 |

| BN025-12 | BN17-24 | BN110-6LT |

| BN025-24 | BN17-48 | BN110-12T |

| BN05-12 | BN26-6L | BN130-6L |

| BN05-24 | BN26-12 | BN130-12 |

| BN1-6L | BN30-6LT | BN130-18 |

| BN1-12 | BN30-12T | BN200-6L |

| BN1-24 | BN35-6L | BN200-12T |

| BN2-6L | BN35-12 | BN202-6L |

| BN2-12 | BN35-24 | BN240-12 |

| BN2-24 | BN35-48 | BN300-6L |

| BN5-6L | BN40-6LT | BN300-12T |

| BN5-12 | BN52-6L | BN400-12T |

| BN5-24 | BN52-12 |

Position number and material list of Seepex wear-resistant parts

| Parts Name | Position | Material |

|---|---|---|

| Stator | 601 | NR, NBR, Q, EPM, FKM |

| Rotor | 600 | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| Coupling Rod Pin | 402 | 45#, 2Cr13, 304, 316L |

| Guide Bushing | 403 | 45#, 2Cr13, 304, 316L |

| Retaining Sleeve | 401 | 45#, 2Cr13, 304, 316L, 2205, Ti |

| Holding Band | 406 | 304, 316L |

| Universal Joint Sleeve | 405 | NR, NBR, Q, EPM, FKM |

| Holding Band | 407 | 304, 316L |

| Coupling Rod | 400 | 45#, 2Cr13, 304, 316L, 2205, Ti |

| Coupling Rod Bushing | 404 | 45#, 2Cr13, 304, 316L |

| Plug-in Shaft | 307 | 45#, 2Cr13, 304, 316L |

| Plug-in Shaft Pin | 309 | 45#, 2Cr13, 304, 316L |

| Splash Ring | 310 | NBR |

| Mechanical seal | Customized according to media |

01.

Large available inventory

Build a PC pump accessories supermarket with sufficient inventory.

02.

Fast delivery

With an efficient logistics network, you can receive your goods in the shortest time.

03.

100% compatible and highest quality

Not only the appearance and size match, but also the quality can be compared.

04.

Perfect after-sales guarantee

Online 24 hours, reply within 2-3 hours at the latest.

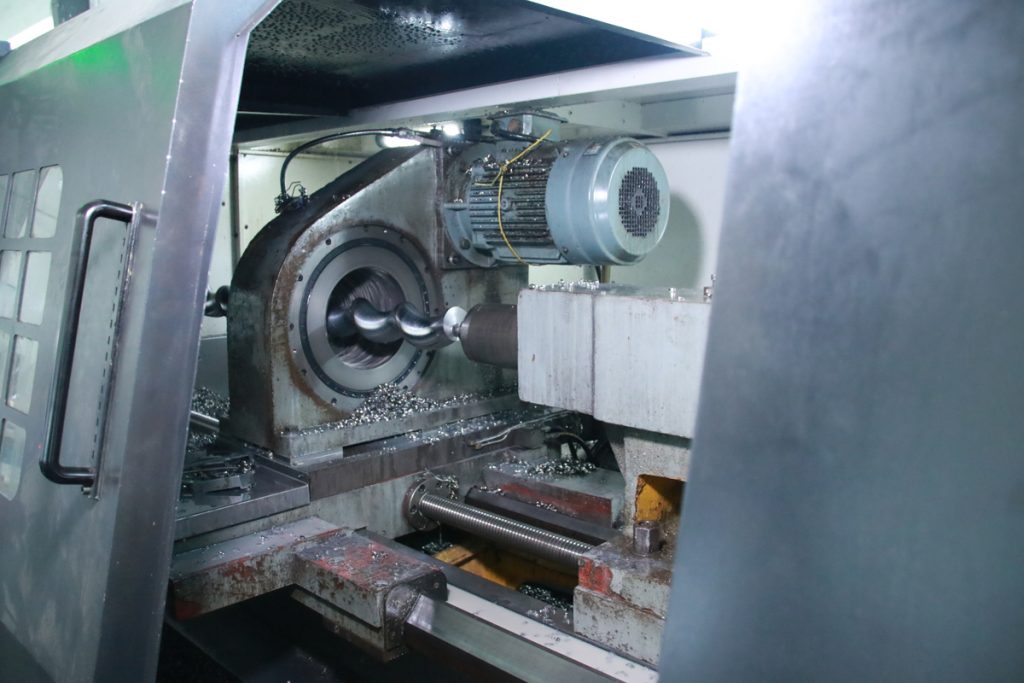

Special rotor machining machine

We have many advanced CNC rotor machining machines.

Special stator production equipment

We have high-precision stator molds and production equipment.