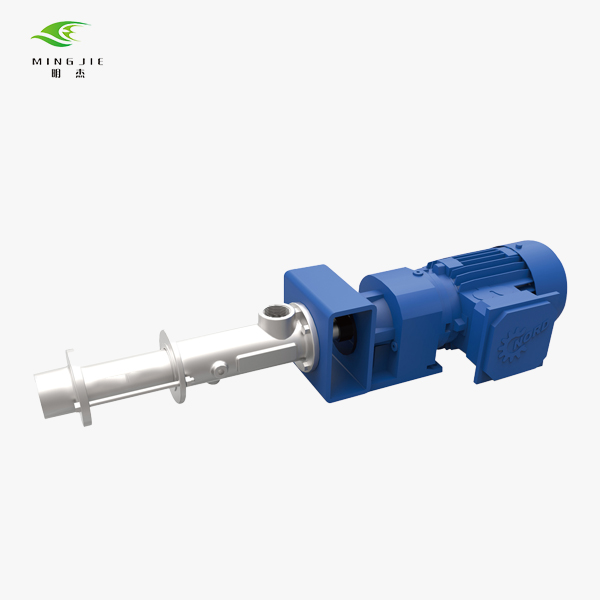

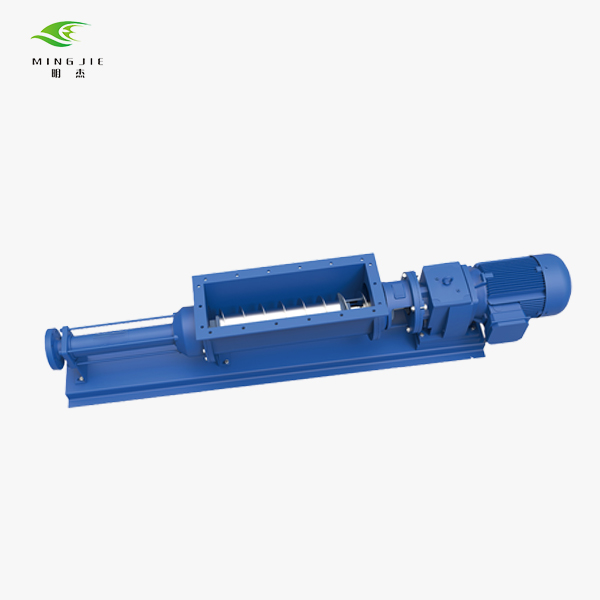

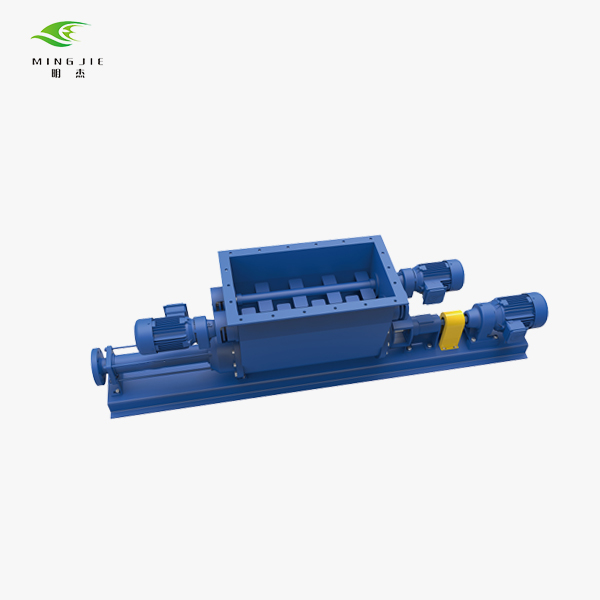

Small Scale Progressive Cavity Pumps for Accurate Dosing

Q=0.04-150 ml/r

P=0~2.0 Mpa (0~290 psi)

Measurement accuracy: <1%

What is a

Small Scale Progressive Cavity Pump for Accurate Dosing?

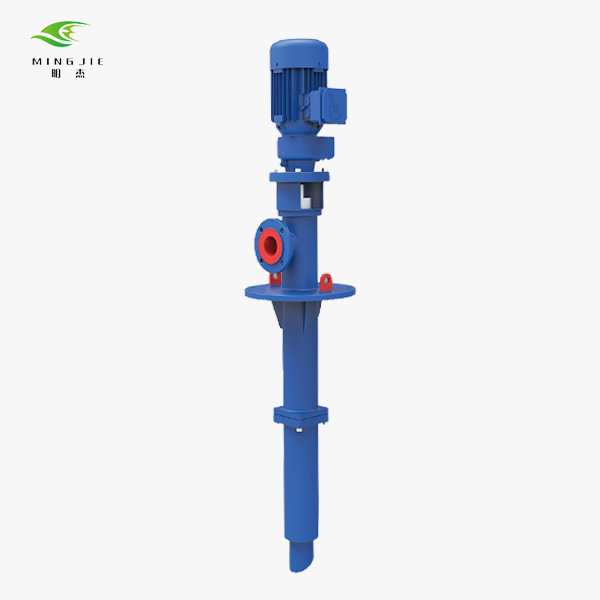

Mingjie Pump has launched a new small-scale progressive cavity pump designed specifically to enable the precise dosing of fluids and pastes proportionate to the rotational speed.

The maximum filler content is 60%. The dosing can be set to be absolutely linear, and the dosing accuracy and repeatability should not exceed 1%.

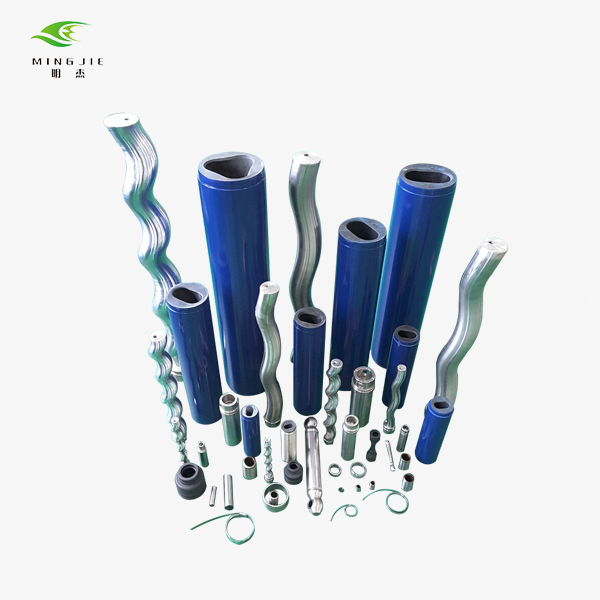

The new technology is based on the volumetric principle of an endless or infinite piston where the rotor and stator components form a sealed metering chamber. The eccentric movement of the rotor allows for a low-shear motion of the medium from one chamber to the next chamber without damage to the media.

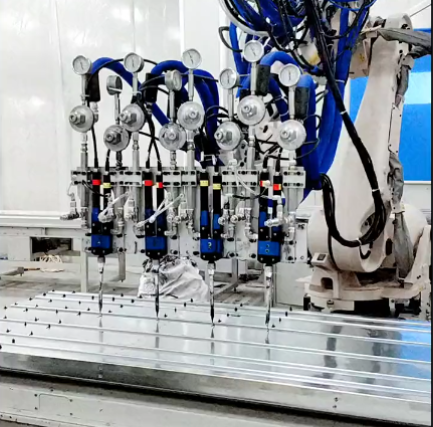

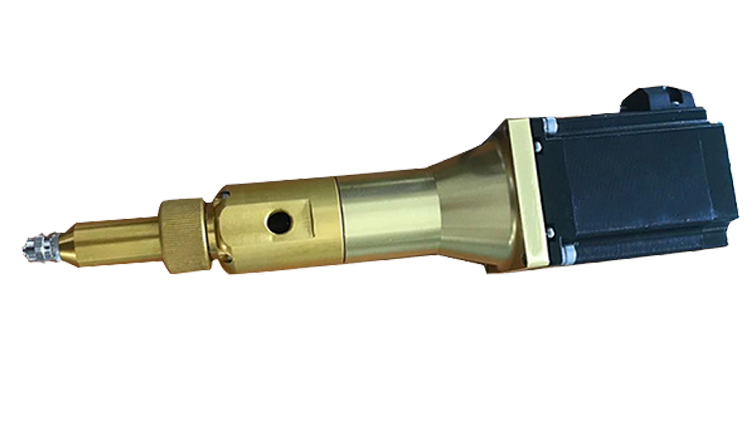

It consists of two parts: driving unit and conveying unit. It is equipped with a needle nozzle and a pump whose liquid output is controlled by a control system.

The Small-scale progressive cavity pump realizes the medium conveying function through the directional rotation of the rotor in the stator cavity.

The transportation process does not have any influence on the medium performance.

At the same time, the reverse rotation of the motor can easily realize the function of medium suction, ensuring the cleanness of medium and materials, no dripping and no pollution!

It is a revolutionary product of viscous flow precision micro-transportation, with a minimum flow rate of 0.001ml and an accuracy of 1%. It has the unique advantages of constant flow rate, being able to suck back, being suitable for granular media, and the flow rate is not affected by changes in viscosity and pressure. It is widely used for precise quantitative transportation, gluing and potting of various fluids.

| Model | Allowable speed | Optimum speed | Recommended dispensing flow | Dispensing pressure | Starting torque |

|---|---|---|---|---|---|

| 0.5 CC | 12~300 rpm | 15~60 rpm | 0.13~0.5 ml/s | 24 bar | ≥ 10 Nm |

| 1.5 CC | 12~300 rpm | 15~60 rpm | 0.38~1.5 ml/s | 18 bar | ≥ 10 Nm |

| 3 CC | 12~300 rpm | 15~60 rpm | 0.75~3 ml/s | 18 bar | ≥ 16 Nm |

| 6 CC | 12~300 rpm | 15~60 rpm | 1.5~6 ml/s | 18 bar | ≥ 20 Nm |

| 12 CC | 12~300 rpm | 15~60 rpm | 3~12 ml/s | 18 bar | ≥ 30 Nm |

| 24 CC | 12~300 rpm | 15~60 rpm | 6~24 ml/s | 18 bar | ≥ 50 Nm |

| 48 CC | 12~300 rpm | 15~60 rpm | 12~48 ml/s | 18 bar | ≥ 100 Nm |

| 96 CC | 12~300 rpm | 15~60 rpm | 24~96 ml/s | 18 bar | ≥ 200 Nm |

| 200 CC | 12~300 rpm | 15~60 rpm | 50~200 ml/s | 18 bar | ≥ 400 Nm |

| Item | MJ-SD PEN150 | MJ-SD PEN300 | MJ-SD PEN450 | MJ-SD PEN650 | MJ-SD PEN750 | MJ-SD PEN1000 | MJ-SD PEN1500 |

|---|---|---|---|---|---|---|---|

| ml/per revolution | 0.004 | 0.012 | 0.05 | 0.15 | 0.3 | 0.75 | 1.5 |

| Flow per revolution | 0.003 ml/r | 0.01 ml/r | 0.06 ml/r | 0.2 ml/r | 0.4 ml/r | 1 ml/r | 1.6 ml/r |

| Adjustable dosing flow range | 0.04~0.4 ml/min | 0.15~1.5 ml/min | 0.5~6.0 ml/min | 1.5~15 ml/min | 3~30 ml/min | 8~75 ml/min | 15~150 ml/min |

| Motor min and max (rpm) | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 |

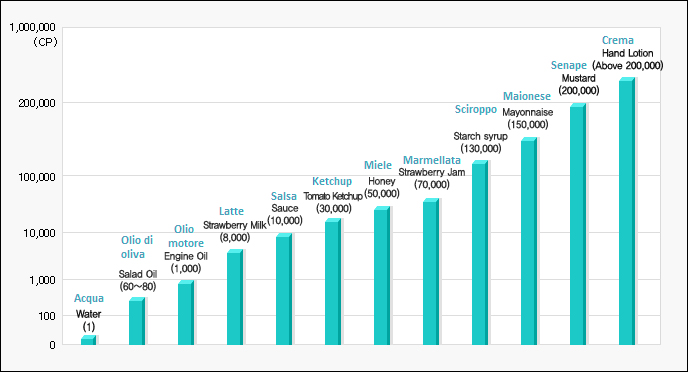

| Recommended fluid viscosity min and max | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps |

| Input Connection | 1/8″ | 1/8″ | 1/8″ | 3/8″ | 1/2″ | 1/2″ | 1/2″ |

| Input min and max pressure | 0-6 bar | 0-6 bar | 0-6 bar | 0-6 bar | 0-6 bar | ≤2.0 mpa | ≤2.0 mpa |

| Output Connection | luer lock with 0 ring | luer lock with 0 ring | luer lock with 0 ring | luer lock with 0 ring | 1/4″ | 1/4″ | 1/4″ |

| Output max pressure | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar |

| Rotor material | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al |

| Stator material | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM |

| Wetted part of body material | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al |

| Weight | 350g | 350g | 400g | 500g | 2300g | 2800g | 3000g |

Medium Viscosity Chart

All kinds of solvents, adhesives, paints, chemical materials, glue stick, etc., including silica gel, EMI conductive adhesive, UV adhesive, AB adhesive, dry glue, epoxy adhesive, sealant, hot adhesive, grease, silver adhesive, red adhesive, solder paste, heat dissipation paste, anti-soldering paste, transparent paint, screw fixative, woodworking adhesive, anaerobic adhesive, acrylic adhesive, anti-wear adhesive and crystal glue.

The micro-dispensing system composed of dispensing pump Preeflow is suitable for various fields of industrial production: mobile phone keys, printing, switches, connectors, computers, digital products, digital cameras, MP3, MP4, electronic toys, speakers, buzzers, electronic components, integrated circuits, circuit boards, LCD screens, relays, speakers, crystal oscillator components, LED lamps, chassis bonding, optical lenses, mechanical parts sealing.