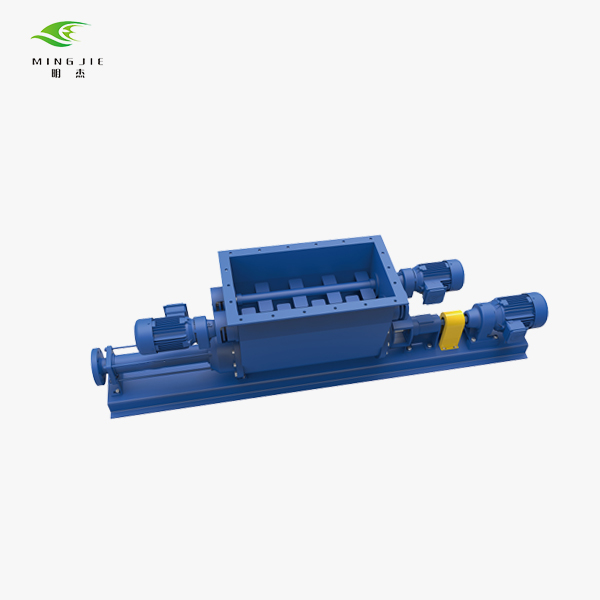

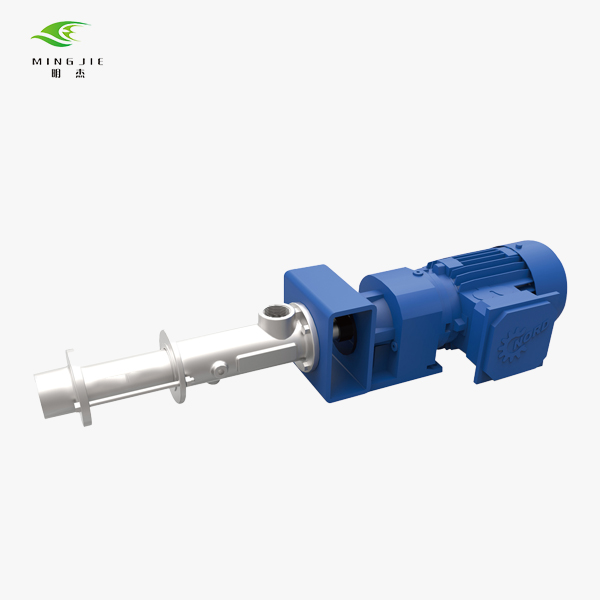

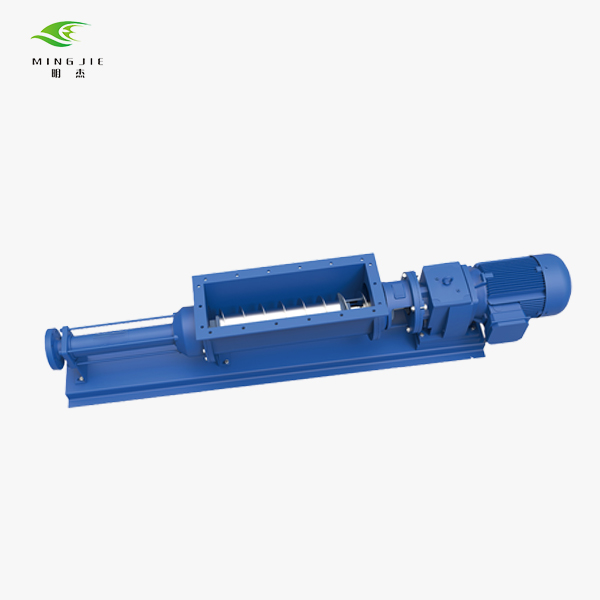

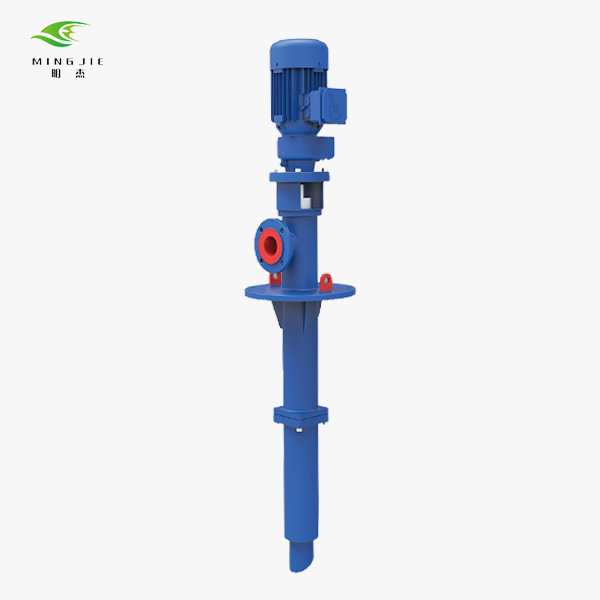

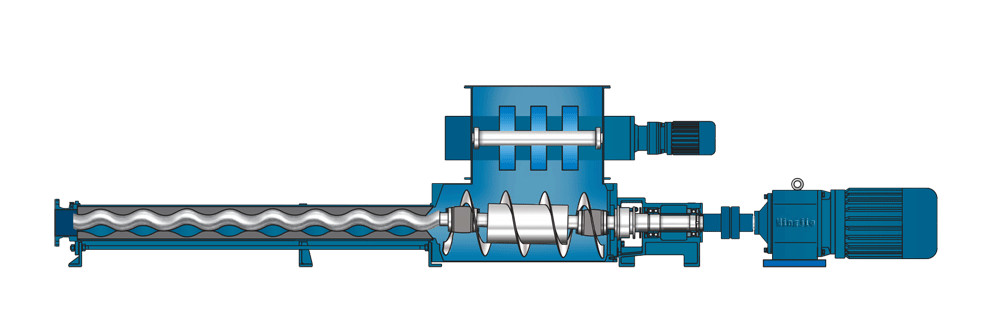

Hopper Pump with Feeding Screw and Bridge Breaking Paddle

Q=0.5-60m³/h (2.2 USGPM – 264 USGPM)

P=0~4.8Mpa (0~700 psi)

What is a

Hopper Pump with Feeding Screw and Bridge Breaking Paddle?

Open hopper feed pump with feeding screw and bridge breaking paddle is equipped with an integrated bridge crusher or agitator on the suction chamber of the feeding screw pump to prevent the bridge from being built and aggregate from being mixed.

| Pump Type | Pressure Range (bar) | Capacity Range (m³/h) | Speed Range (rpm) | Inlet Size (G/DN) | Outlet Size (G/DN) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| MJN025-2S | 0~12 | 0~0.25 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-1L | 0~6 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-2S | 0~12 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-1L | 0~6 | 0~1 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-2S | 0~12 | 0~1 | 0~350 | 50 | 50 | 1.5 |

| MJN1-4S | 0~24 | 0~0.5 | 0~250 | 50 | 50 | 3 |

| MJN3-1L | 0~6 | 0~3 | 0~350 | 50 | 50 | 2.2 |

| MJN3-2S | 0~12 | 0~2.5 | 0~350 | 65 | 65 | 3 |

| MJN3-4S | 0~24 | 0~1.5 | 0~250 | 65 | 65 | 5.5 |

| MJN5-1L | 0~6 | 0~5 | 0~320 | 65 | 65 | 3 |

| MJN5-2S | 0~12 | 0~5 | 0~320 | 80 | 80 | 4 |

| MJN5-3S | 0~18 | 0~3 | 0~250 | 80 | 80 | 5.5 |

| MJN5-4S | 0~24 | 0~2 | 0~200 | 80 | 80 | 7.5 |

| MJN10-1L | 0~6 | 0~10 | 0~300 | 80 | 80 | 4 |

| MJN10-2S | 0~12 | 0~7 | 0~300 | 80 | 80 | 5.5 |

| MJN10-3S | 0~18 | 0~6 | 0~250 | 80 | 80 | 7.5 |

| MJN10-4S | 0~24 | 0~4 | 0~200 | 80 | 80 | 11 |

| MJN15-1L | 0~6 | 0~15 | 0~300 | 80 | 80 | 5.5 |

| MJN15-2S | 0~12 | 0~12 | 0~300 | 100 | 100 | 7.5 |

| MJN15-3S | 0~18 | 0~10 | 0~250 | 100 | 100 | 11 |

| MJN15-4S | 0~24 | 0~7 | 0~200 | 100 | 100 | 15 |

| MJN25-1L | 0~6 | 0~25 | 0~280 | 100 | 100 | 7.5 |

| MJN25-2S | 0~12 | 0~22 | 0~300 | 125 | 125 | 11 |

| MJN25-3S | 0~18 | 0~15 | 0~250 | 125 | 125 | 15 |

| MJN25-4S | 0~24 | 0~12 | 0~200 | 125 | 125 | 18.5 |

| MJN50-1L | 0~6 | 0~50 | 0~280 | 125 | 125 | 11 |

| MJN50-2S | 0~12 | 0~35 | 0~250 | 150 | 150 | 22 |

| MJN50-3S | 0~18 | 0~30 | 0~230 | 150 | 150 | 30 |

| MJN50-4S | 0~24 | 0~26 | 0~200 | 150 | 150 | 37 |

| MJN80-1L | 0~6 | 0~80 | 0~280 | 150 | 150 | 22 |

| MJN80-2S | 0~12 | 0~60 | 0~280 | 150 | 150 | 37 |

| MJN80-3S | 0~18 | 0~42 | 0~200 | 150 | 150 | 45 |

| MJN80-4S | 0~24 | 0~25 | 0~150 | 150 | 150 | 55 |

| MJN120-1L | 0~6 | 0~120 | 0~250 | 150 | 150 | 37 |

| MJN120-2S | 0~12 | 0~100 | 0~270 | 200 | 200 | 45 |

| MJN120-3S | 0~18 | 0~60 | 0~180 | 200 | 200 | 55 |

| MJN120-4S | 0~24 | 0~50 | 0~150 | 200 | 200 | 55 |

| MJN180-1L | 0~6 | 0~180 | 0~220 | 200 | 200 | 45 |

| MJN180-2S | 0~12 | 0~170 | 0~220 | 200 | 200 | 55 |

| MJN300-1L | 0~6 | 0~300 | 0~220 | 200 | 200 | 55 |